Quality Assurance for Waterproofing Systems

Waterproofing... What can go wrong?

Design Phase

This is where it all begins. If the design and detailing are not properly drawn and communicated, the probability of failure with a quality application and installation is greatly increased. The most common problem that contractors and subcontractors face with installing waterproofing systems in new and renovation construction is the lack of project-specific details at critical transitions. Frequently, designers omit unusual intersections and penetrations from construction documents or provide details with constructability issues that will need to be "worked out" in the field.

Example 1:

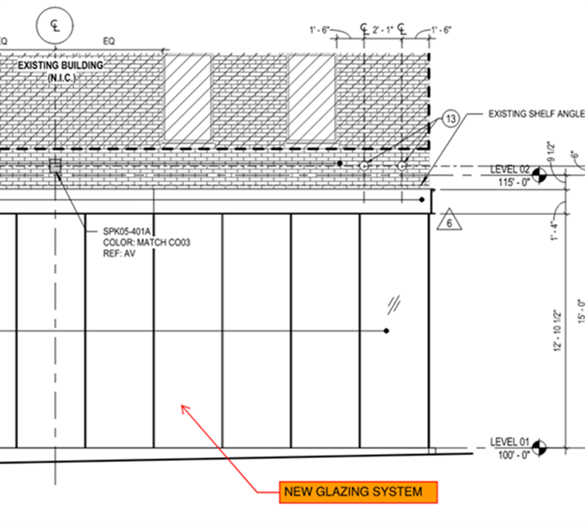

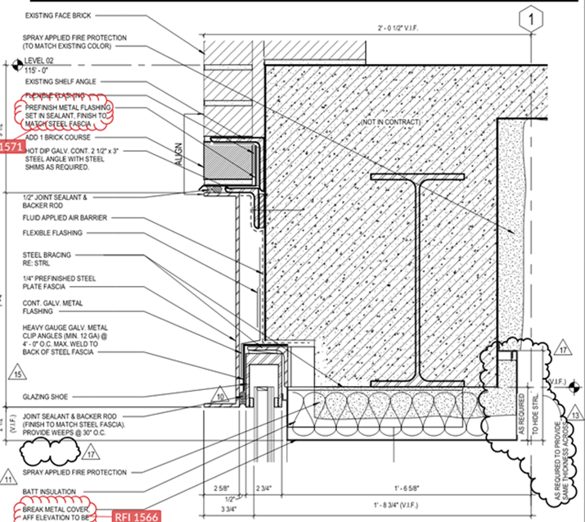

Many historic buildings are renovated and brought back to life. When one of these buildings is approved for renovation, steps must be taken and considered. Typically, those steps include bringing a building's performance up to code, increasing thermal performance, and keeping the exterior aesthetically exactly how it was when the building was originally built. These steps can be challenging when opening up walls and working within the shell that exists. In these instances, detailing the correct assemblies while showing the new product in existing structures, with the feasibility of installation in mind, is extremely critical. A historic building in downtown Dallas was renovated recently. The construction modification included a retrofit new glazing system (Figure 1). The architect developed the detail (Figure 2) for this specific assembly; however, it was not based on the evaluation of the air and moisture behavior of the existing wall system and, in turn, created installation challenges for the contractor during an advanced stage of construction. This situation caused both construction schedule delays and quality compromises. Although the contractor attempted to provide a solution that they believed would be adequate, the field performance water penetration testing resulted in a failure of the glazing system. This could have been mitigated during the Design Review Phase, with a collaborative understanding of the interaction between the new and existing building materials and assemblies. Efforts should be made, as a team, to provide details before construction modification that could affect the in-place wall systems' behavior. The Design Phase is intended to address the 3 C's, Continuity, Compatibility, and Constructability.

Figure 1: Partial elevation

Figure 2: Architectural retrofit glazing detail

Example 2:

As buildings are expanded, sites are renovated, or brand-new buildings are being constructed, a designer must look beyond products and aesthetics. Sometimes they need to address the proper expansion joint to connect a new and old building, paying close attention to disrupting adjacent structures in excavation or avoid penetrating important assemblies that already exist, not shown in the design. Architects have a lot of responsibility during the design phase, and one of them is ensuring they reflect the correct integrated details, notes, instructions, and specifications. After all, contractors are contractually bound by plans and specs.

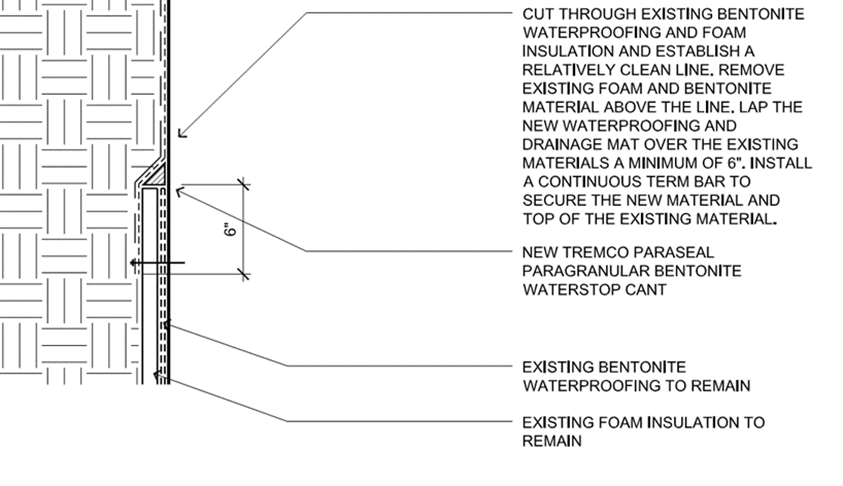

A large plaza was expanded to include a new planter and water features. The new extension required expanding the waterproofing system at the basement walls. The waterproofing subcontractor could not integrate the new bentonite sheet membrane into the existing waterproofing system, as indicated in the architectural detail (Figure 3). Cutting the existing bentonite waterproofing and establishing a relatively clean line was not feasible due to the existing system's condition. In the middle of construction, the contractor was presented with a dilemma: Option 1 - Replace the waterproofing system along with the 30 ft deep basement wall, which would result in a long and costly excavation operation, or Option 2 – Stop the excavation at a relatively early stage, which would save money; however, it meant dealing with a high-risk condition, which was the weak link joint between the existing and new waterproofing membrane. Which do you think the contractor chose?

Figure 3: Architectural transition detail

The moral of the stories: To avoid scenarios that may increase the risk of loss of quality and performance, Quality Assurance programs designed to evaluate and resolve problems can start as early as the Design Phase. An effective program includes the following basic steps:

- Evaluate project criteria that establish characteristics of the acceptable end-product.

- Implement periodic reviews and approvals for the criteria and design during development.

- Review the schedule for completion of the project and compare it with feasibility.

- Schedule Building Envelope consultant reviews and performance testing.

In addition, contractors and subcontractors should be required to demonstrate their knowledge of the materials, products, and systems to be installed through the submittal process. Problems must be resolved during this phase, not on the job site.

Construction Phase

During the construction phase of a project, waterproofing installation quality tends to be overlooked by many in comparison to other project aspects. Therefore, this creates opportunities for errors to occur and problems to develop, which can dramatically affect the installed waterproofing systems' ability to provide the required performance, maintain its warranty, and create adjacent materials failures within the same assembly. The goal in the construction phase is to avoid sending that same building through a leak-chasing event in a fully occupied space or, even worse, litigation!

A significant amount of waterproofing system failure is attributed to installation errors. Even the most elaborate details and thorough drawings and specifications are of little use when workers fail to care for materials and installation. It should be encouraged or even specified that contractors and subcontractors are required to demonstrate their knowledge of the materials, products, and systems to be installed through the submittal process. When individuals are not properly trained to install a particular assembly, the risk of system failure increases. Some of the installation errors that might be observed during construction include, but are not limited to:

- Installing waterproofing systems without properly preparing substrates

- Applying adhesives or primers for self-adhered systems improperly

- Applying the self-adhered membrane before the primers' readiness

- Non-compliant waterproofing system installation, as it relates to project construction documents

- Penetrations not properly sealed, or not sealed at all

These factors can result in costly waterproofing system failures and should be resolved prior to the construction phase.

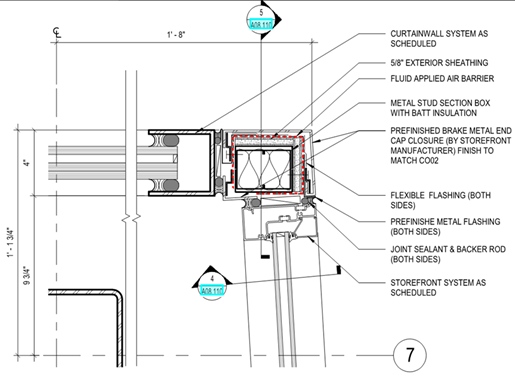

In this condition (Figure 4), a detail was developed to show all materials in the assembly; however, the storefront system was installed before applying a weather barrier system at a corner post, creating weather envelope discontinuity. The Construction Phase should ensure communication in sequencing and constructability.

To correct the installation, the subcontractor had to remove the glazing system to allow the installation of a weather barrier system around the corner post. To avoid this type of error in the future, which could contribute to costly construction schedule delays, a Quality Assurance program should be in place, requiring a construction document and including Installation Instructions, to be on-site at all times. (Figure 5) Photo showing the self-adhered vapor permeable membrane not wrapping the opening as depicted in the architectural detail (Figure 4).

Figure 4

Figure 5

The Failure Phase

This is not a phase we want to get to…unless we are performing a test to failure, deliberately. Unfortunately, by the time a failure phase occurs, mayhem may have occurred as well, including air & water infiltration which can cause humidity buildup in the walls, organic substances, and damage to the overall assemblies. Demolition research and installation of new materials or assemblies are often the repairs. Causes for waterproofing systems failure, or lack of performance as expected/intended include:

- Wrongly specified performance criteria

- Incorrect selection of materials or system

- Inadequate detailing

- Insufficient communication between trades for coordination of interface

- Compatibility issues of adjacent materials

- Lack of proper delivery and storage procedure

- Improper temperatures for installation

- Damage by other trades after installation (Figure 6)

Proper waterproofing system selection and detailed designs, including appropriate quality and performance levels, are the first steps toward a successful building envelope system. A sound Quality Assurance program is essential for reviewing and monitoring the work for conformity during the construction phase. This ensures the design intent is met and constructability performance is inclusive of approvals and communications. Keep in mind, that not all Quality Assurance programs are alike; however, here are some general guidelines that might protect the building from a failure phase:

- Preconstruction meeting before the arrival of waterproofing material.

- Review typical details and critical waterproofing details with contractors and subcontractors.

- Review work regularly to ensure conformance to project requirements.

- Review storage conditions and requirements.

- Review problem resolution techniques and procedures to be followed for successful project completion.

- Schedule and hold regular progress meetings to review the status of envelope work as it proceeds.

- Protect finished products and limit traffic by different trades that can cause damage.

Figure 6: Workers walking on top of self-adhered vapor-permeable membrane, not protecting from material intrusions.

.

Subscribe Today!

Stay-in-the-know and subscribe to our blog today!